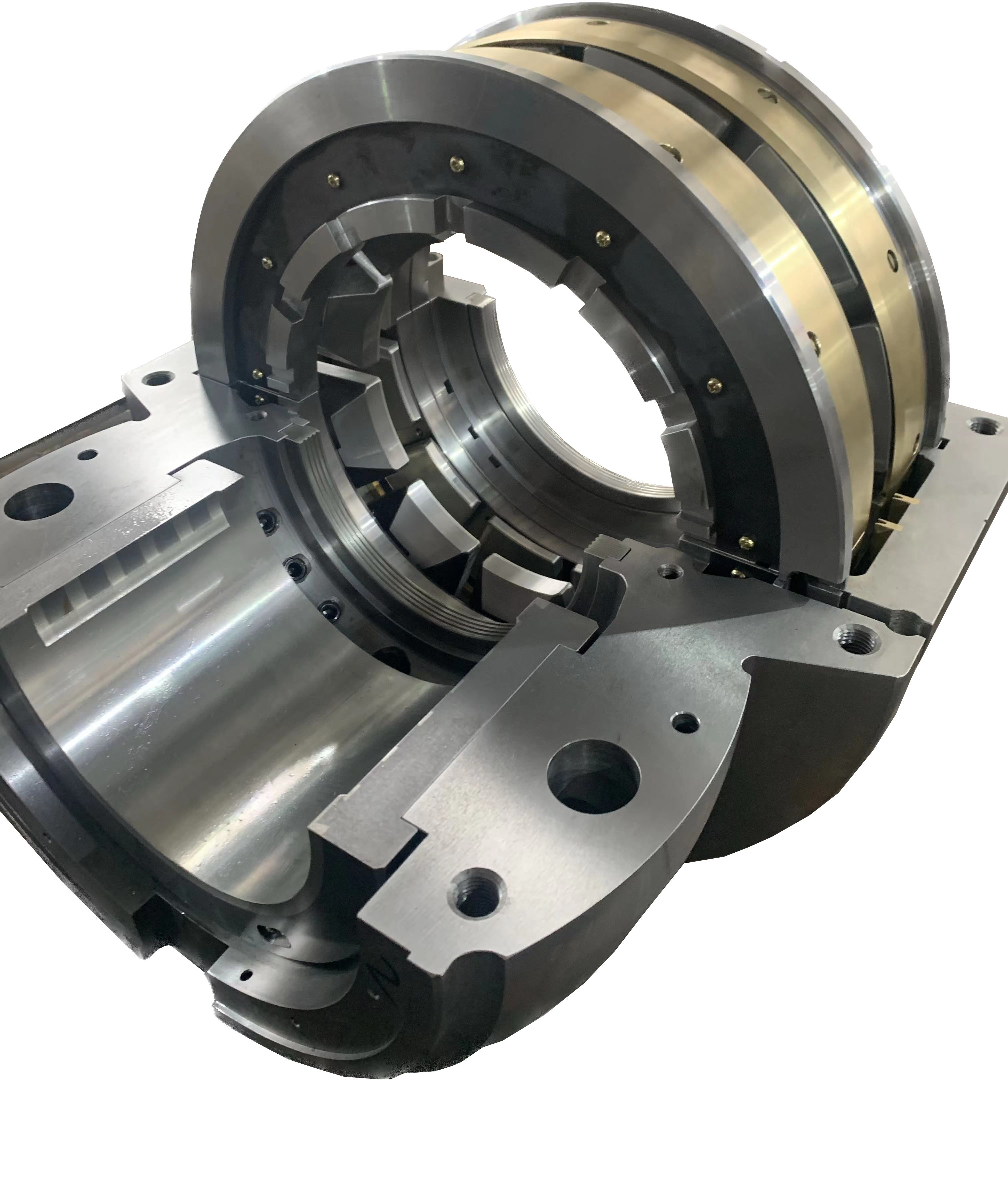

spare parts

We maintain a comprehensive inventory of steam turbine components, including blades, seals, bearings, and control valves, all certified to CE or ISO standards. Rapid logistics support ensures critical spares are available on demand to minimize unplanned downtime.

maintenance

Our maintenance program leverages vibration analysis, thermography, and lube-oil particle analysis to detect early signs of wear. Technicians perform inline inspections, clearance/alignment checks, and dynamic balancing with calibrated tools to ensure reliability.

overhaul

Full teardown and rebuild services include borescope inspection, rotor straightening, and blade refurbishment. We replace or refurbish critical assemblies like turbine wheels, diaphragms, diaphragms, and gearboxes per specifications.

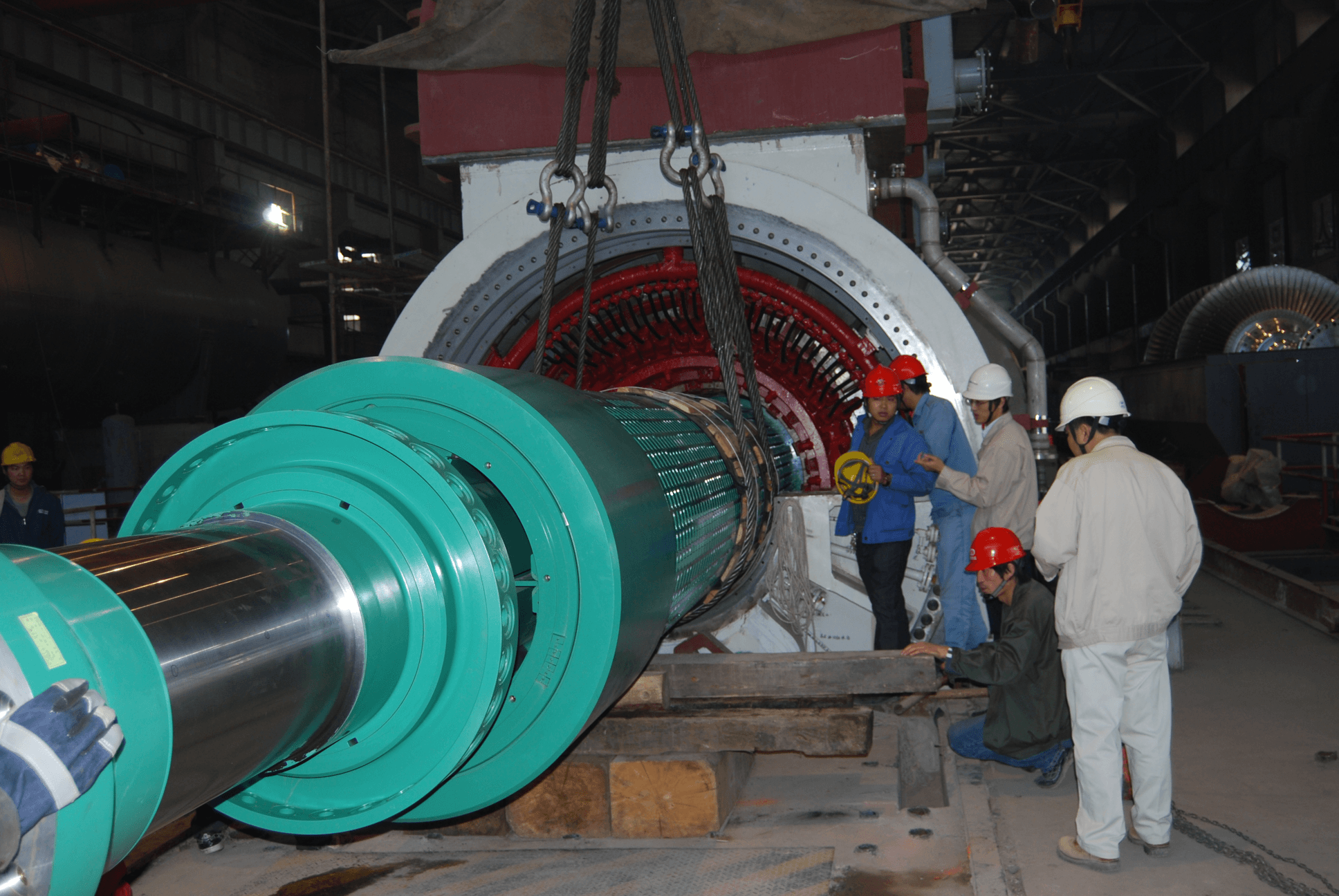

efficiency and capacity upgrade

Our upgrade packages retrofit optimized blade profiles, nozzle geometry, and steam flow path to boost thermal efficiency and power capacity. We retrofit new digital control system to enhance load response and turndown capability.

send us a message

Get in touch with our skilled, experienced, and excellent after-sales service team, waiting to serve all customers’ needs, providing users with fast and high-quality services at any time!

Follow-up services are carried out throughout the whole process of commissioning, manufacturing, transportation and installation for all QNP projects to ensure customer satisfaction.