Overhaul Services

QNP provides you with all-round unit maintenance and overhaul services professionally, as well as upgrading and transforming services for old units. At the same time, QNP also provides customers with long-term training and commissioning services, and can make maintenance and overhaul plans , implement one-to-one service, and directly provide lifelong service to users according to their requirements.

QNP provides design, renovation and upgrading, maintenance, overhaul, spare parts supply and other services for steam turbine generator units below 1000MW.

QNP has various high-precision equipment such as CNC heavy horizontal lathe, CNC vertical lathe, large CNC boring machine, Mitsubishi high-precision gantry machining center etc., which can undertake the machining business of machine units below 1000MW.

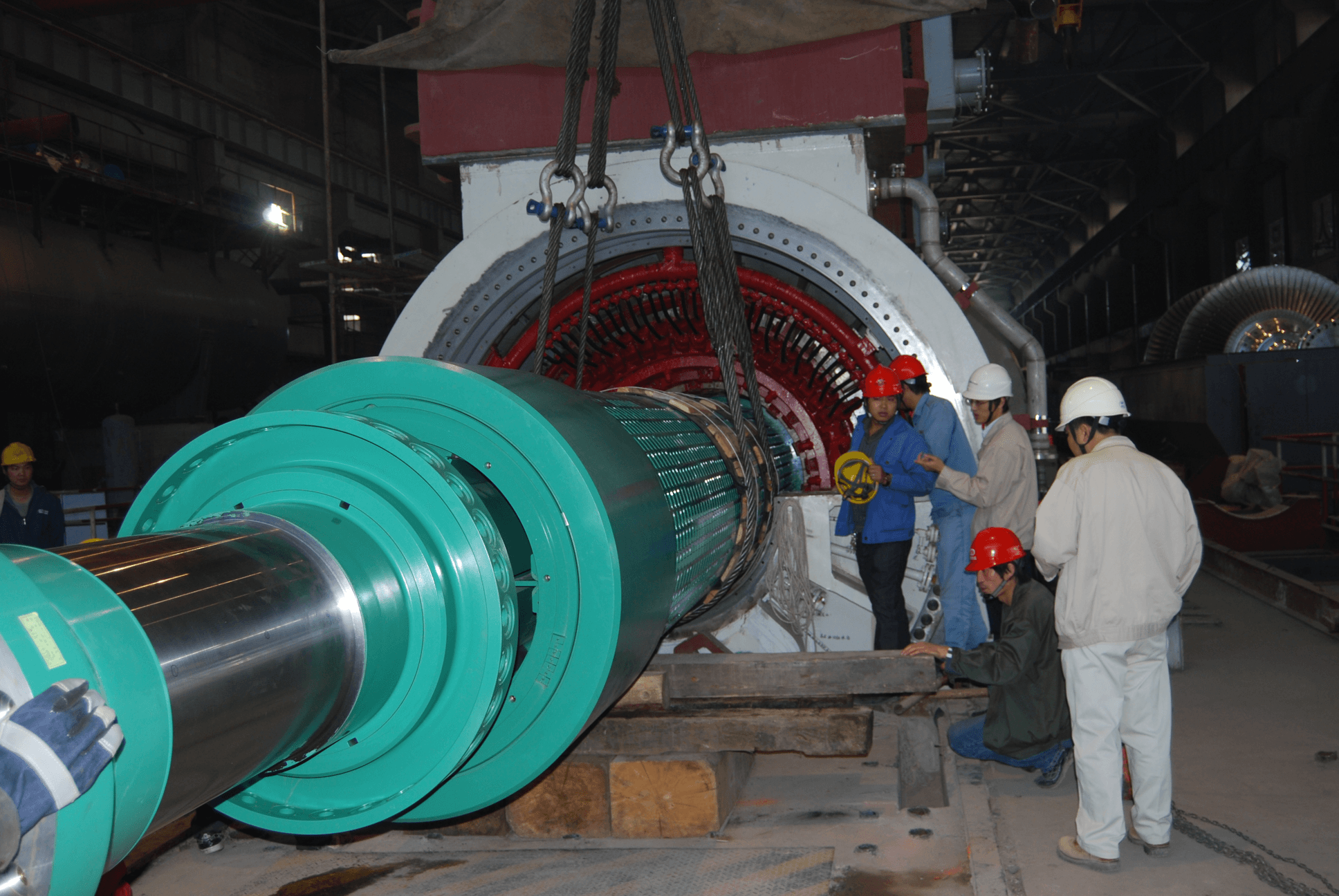

steam turbine overhaul

The overhaul contents include the common and difficult faults including steam turbine parts supply, steam turbine installation, overhaul, technical transformation, project general contracting, steam turbine accident treatment, steam turbine technical training, steam turbine low lubricating oil pressure transformation, repair of steam turbine rotor shaft bending, reduction of vibration and noise of steam turbine units, elimination of abnormal fluctuation and load swing of speed regulation system, and solution of insufficient steam turbine output and load etc.

Unit maintenance process

Customer information provision→on-site inspection→issue overhaul plan→prepare overhaul process→equipment disassembly and assembly inspection and repair→installation inspection→commissioning and acceptance

Synchronous Generator Overhaul

Generator stator and rotor coil inspection, rotor fastening inspection, insulation material or insulation part loss inspection, rotor runout inspection, stator air tightness inspection, hydrogen (air) cooler inspection, generator test, etc.

Unit overhaul process:

Customer information provision→on-site inspection→issue overhaul plan→prepare overhaul process→equipment disassembly and assembly inspection and repair→installation inspection→commissioning and acceptance

Overhaul of speed regulation system

We provide full overhaul to improve the efficiency, durability and reliability of the following systems:

a. speed regulation, security system

b. Main stop valve

c. Oil system

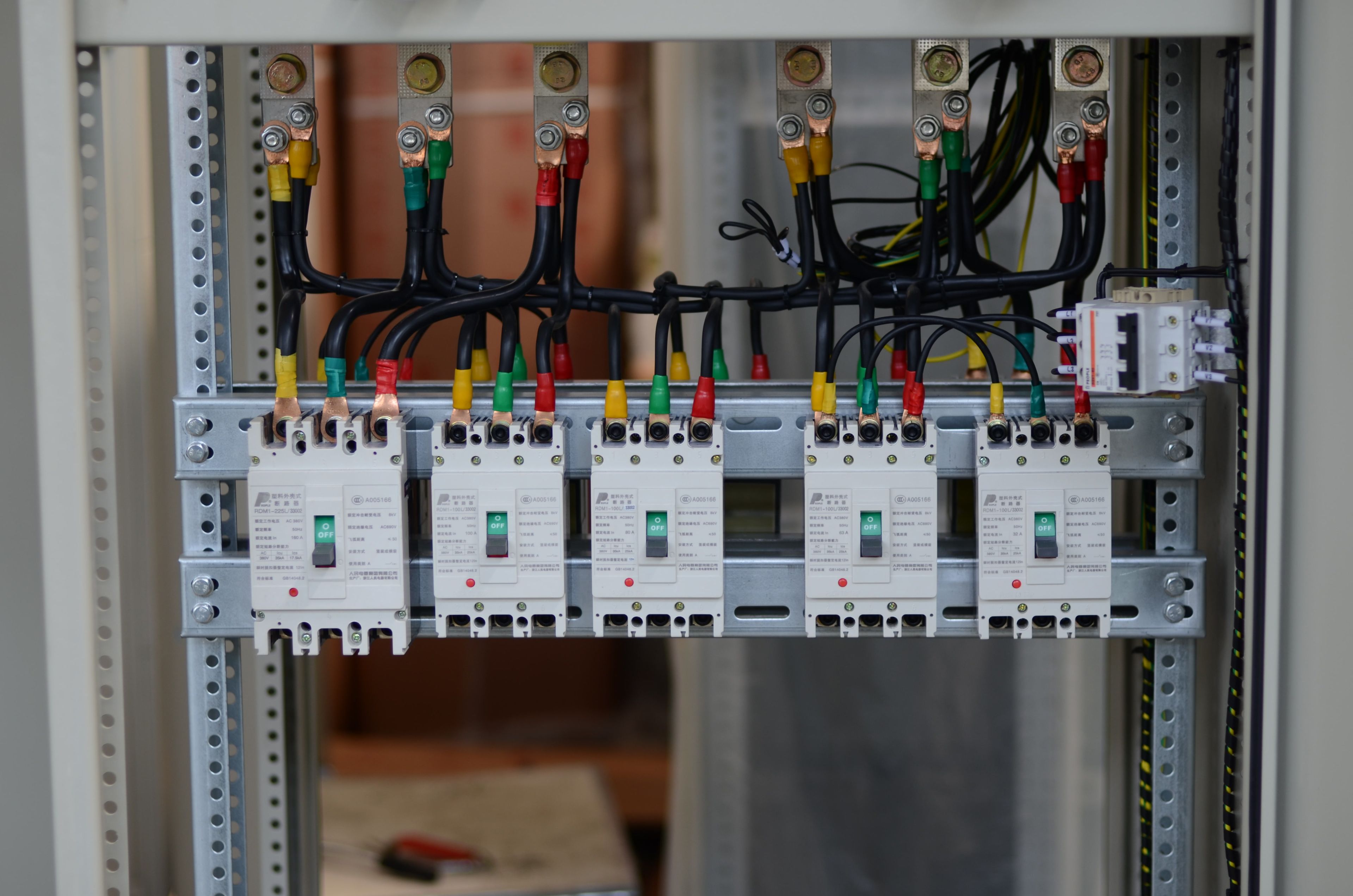

Overhaul and test of electrical system

The safe operation of electrical equipment of steam turbine generator set is related to the safety of electricity consumption. The preventive test regulations of power equipment clearly put forward the test contents and cycles of various power equipment to avoid the occurrence of power faults to the greatest extent. Generator is the "heart" of power system, and its safe operation will directly affect the stability of power system and the quality of electric energy. The mechanical structure of the generator itself is complex, and there are huge auxiliary equipment, which makes the condition that the failure of any component of the generator system may lead to the whole system stopping operation. As a designer and manufacturer of generator and electrical cabinet, QNP has rich experience to deal with various electrical failures, and can undertake a variety of test projects.

send us a message

Get in touch with our skilled, experienced, and excellent after-sales service team, waiting to serve all customers’ needs, providing users with fast and high-quality services at any time!

Follow-up services are carried out throughout the whole process of commissioning, manufacturing, transportation and installation for all QNP projects to ensure customer satisfaction.